The precision machining industry plays a huge part in all methods of power generation. From geothermal and solar power, to hydro and wind energy, each one can benefit from the wealth of features that CNC manufacturing can offer.

Offshore energy is no exception. This extremely important industry has grown dramatically in recent years, especially in the UK. But exactly how can precision engineering help this essential sector?

The Importance of the Offshore Energy Sector

As a society, we have become increasingly reliant on fossil fuels in our pursuit of technological advancement. This has contributed to global warming and climate change, meaning that countries throughout the world are trying to cut back on the use of these traditional fuels and seek out alternative sources of energy.

The offshore energy sector is of particular importance in the UK, given the fact it is an island and surrounded by the sea. This gives the country a fantastic opportunity to harness the offshore wind and generate green electricity to power our homes and businesses.

In 2019, government data revealed that wind generators accounted for one fifth of the UK’s total power generation, and became the country’s second largest source of electricity.

5 Benefits of the Precision Machining Industry

There are many ways in which the precision machining industry can support the offshore energy sector. This is due to the several unique benefits and procedures involved. Here are just a few:

Reduced Human Error

Using techniques such as CNC machining enables the precision engineering sector to considerably reduce the risk of human error when creating the parts. While manual engineers are still incredibly skilled, mistakes do happen and these can cause delays to the production process.

The process of CNC manufacturing also means there is little need for human supervision, since modern-day machinery can take care of even the most demanding tasks with ease. All of the cuts that are required to make the components are pre-planned as well, before the machining even takes place. This means that any potential pitfalls can be identified and corrected right away, further reducing the risk of errors.

Fewer Test Runs

Traditional forms of manufacturing can quite often need several test runs to ensure that everything produced conforms to the exact specifications and requirements. This is because the engineer will often make several mistakes in their first few attempts and will need to familiarise themselves with the required process to create the items. For an industry like the offshore energy sector, which will often require products to be delivered within tight timeframes, this is less than ideal.

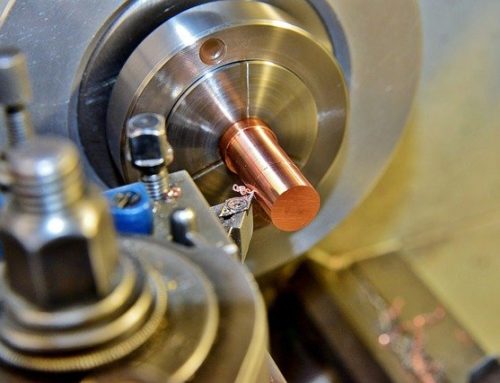

The precision machining industry allows engineers to reduce the number of test runs via the use of CNC milling and CNC turning. Machine operators can use visualisation systems that allow the engineer to see beforehand whether the component is going to match the specifications or not. This can potentially save a lot of time and money.

Durability

Offshore wind farms are subjected to extremely harsh weather conditions every single day. From high winds and rain to the constant battering from waves, it is vital that the turbines can withstand the pressure. After all, if there is a failure in the system, it could cause severe disruptions to the power supply.

The precision machining industry is accustomed to creating parts and components of the highest quality that are built to stand the test of time. Precision engineering companies take pride in the quality of their products and understand the need for durability. This means they will never let any items leave their workshops if they are not completely confident in their quality.

The vast majority of companies in the precision machining industry will employ robust quality control procedures that they have honed over the years to ensure that they take advantage of the latest technological advancements and best practices. They will also cultivate a sense of pride in their employees to ensure that everything produced is fit for purpose. All of these factors ensure that the offshore wind industry can be totally confident that the components they receive will do exactly what is required of them.

Lower Costs

The precision machining industry can significantly reduce the costs incurred by the offshore energy sector. Because everything is so intricate and comprehensive, there will be a lot less wastage and a reduced need for labour.

In order to stay competitive in the industry, the vast amount of precision engineering companies will pass on these savings to their clients. These firms will also be looking to consistently upgrade their services to take advantage of the latest technologies, which will inevitably lead to even lower costs.

Intricacy

The offshore energy sector has a real requirement for small and intricate parts, especially when it comes to the wind turbines themselves. Precision engineering makes this a possibility and enables manufacturers to create components with pinpoint accuracy.

Products Manufactured for the Offshore Energy Sector

The precision machining industry provides a wide range of components for the offshore industry. These include everything from contacts and contact plugs, to half clamps and standard pins.

Why Work with EGL Vaughan

If you are looking for precision-made components for the offshore energy sector, you can rely on EGL Vaughan to help. We have amassed over 40 years of experience in delivering high-quality products for the industry and understand its unique requirements inside and out.

We are passionate about every single item we produce, and have developed a robust quality control procedure that ensures our products can conform to even the tightest of specifications – first time, every time. This attention to detail has enabled us to become the trusted supplier of some of the biggest names in the energy sector. In addition, we have also received numerous accreditations from important manufacturing bodies.

Trust plays an incredibly important part in the precision machining industry, which is why we are committed to building lasting relationships with all our clients. We will use all of our expertise to recommend the right solutions for you, and offer professional advice and guidance throughout the entire manufacturing process. It is this level of support that ensures our clients return to us time and time again.

For more information about EGL Vaughan can help you, contact a member of our team today or request a rapid quote.