Precision-turned components are essential for the production of high-quality, precision-engineered products. These components are manufactured using CNC turning, a process that uses computer-controlled lathes to create intricate and precise parts. The process offers unparalleled accuracy and repeatability, making it ideal for the production of components used widely across various industries.

What are Precision Turned Components?

These small parts are made from a variety of materials, including metals, plastics, and composites. These components are used in a wide range of applications, from aerospace and automotive to medical and defence. They can include anything from bolts and screws, to hydraulic and pneumatic components, valves, and fittings.

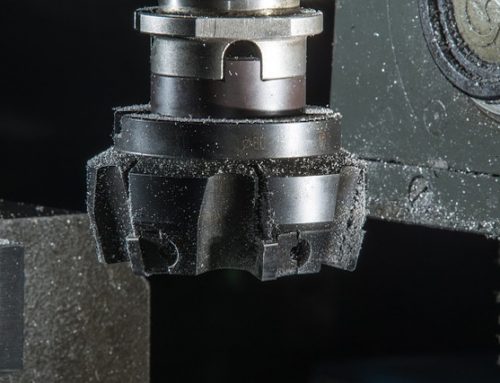

They’re produced using CNC turning, a process that involves using a computer-controlled lathe to shape and cut the component. CNC turning is ideal for producing precision-turned components, as it offers high accuracy, repeatability, and consistency across multiple parts.

Advantages of Precision-Turned Components

- Accuracy and repeatability: Precision-turned components are manufactured using CNC turning, a process that offers high accuracy and repeatability across multiple parts.

- Consistency: CNC turning ensures that each component is produced with the same level of precision, resulting in consistent and reliable parts.

- Speed and efficiency: These machines can produce parts quickly and efficiently, reducing lead times and improving productivity.

- Versatility: Precision-turned components can be manufactured from a wide range of materials, making them suitable for a variety of applications.

- Cost-effective: CNC turning offers a cost-effective way to produce precision-turned components, reducing labour and material costs.

Applications of Precision-Turned Components

- Aerospace: The manufacture of aircraft engines, landing gear, and other critical components.

- Automotive: Engine components, transmission systems, and steering systems, among others.

- Medical: Surgical instruments, medical devices, and implantable devices.

- Defence: Military vehicles, weapons systems, and other defence-related applications.

EGL Vaughan is part of the GJ Engineering Group which, across the businesses within the group, manufactures a wide variety of parts and components, spanning each of the industries mentioned. For more information on any of the above, please get in touch today.