Reverse Engineering

If you need to recreate a part without technical drawings, EGL Vaughan’s reverse engineering services can help.

| Fast turnaround | UK Manufactured |

|---|

| High Quality | Cost-Effective |

A Trusted Precision Engineering Supplier to Some of the UK’s Leading Companies

Reverse Engineering Services in the UK

No matter why you are looking for reverse engineering services, you can rely on EGL Vaughan to help. We’ve helped countless clients from all areas of industry with issues such as legacy components, digital archiving and much more – and are perfectly placed to assist you as well. Our approach to quality and customer service has seen clients return to us time and again, so you can rely on us to deliver.

We’ve amassed over 40 years of experience in the precision engineering industry, using the time to hone our skills and become one of the most respected manufacturers the UK has to offer. We are proud to demonstrate the best of British manufacturing and are capable of producing high-quality parts and components that match even the most demanding of requirements and specifications – first time, every time.

Common Uses

- Legacy Components

- Original Equipment Manufacturer (OEM) Issues

- Digital Archiving

- Competitor Analysis

- Bespoke & Ancient Objects

- Additive Manufacturing

Recieve a Custom Quote

Need a precision engineered component? Click below to receive a rapid quote from our team.

Or Call: 0161 511 5311

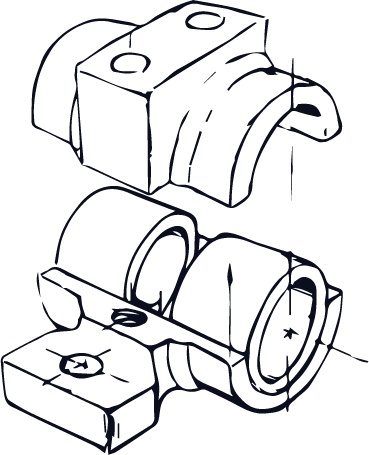

What is Reverse Engineering?

In the world of precision engineering, reverse engineering is the process of taking apart a product in order to find out how it is designed and made. Once this has been deduced, it will then be possible to mass produce the item to meet the exact specifications.

While regular engineering involves the creation of parts and products using precise diagrams and measurements, reverse engineering is the opposite. It is predominantly used where technical drawings are not available and there is no way of knowing how the item was made.

Reverse Engineering begins by obtaining dimensional information of the item. The product is also taken apart to assess its internal mechanisms. Once all the information has been obtained, the data is used to make CAD drawings to help the manufacturing process.

What are the Main Uses of Reverse Engineering Services?

The process of reverse engineering enables manufacturers to duplicate an existing part by capturing its material properties, physical dimensions and features. One of the most common uses of the service is in the case of legacy components that were manufactured a long time ago and for which there are no existing digital instructions available. Manufacturers will use reverse engineering techniques to obtain the required information to not only recreate the component, but also establish digital specifications so the item can easily be created again in the future.

Reverse engineering services can also be called upon if the original equipment manufacturer (OEM) has gone out of business or has lost their design measurements. Manufacturers will use reverse engineering to provide the essential product information to continue building the item. In addition, a company can utilise the process of reverse engineering to analyse their competitors’ products.

Another use of reverse engineering services is dealing with ancient and bespoke objects. If an item is organic in shape (meaning it does not have a standard geometry such as a cylinder or cuboid), it can be extremely difficult to use CAD software to get an accurate representation of the component’s dimensions. Reverse engineering solves this problem by using the existing part as the source and creating digital instructions from there.

Advantages of Reverse Engineering

Reverse engineering services provide engineers and clients with a number of important benefits. One of the most important of these is in the replacement of legacy components. Many businesses will still typically use old machinery as part of their production processes that are no longer supported by their OEM. If a component in one of these machines should fail, the company is in a race against time to get everything back up and running as soon as possible.

The use of reverse engineering also enables manufacturers to improve their process and machines, and implement new processes. It also helps them keep a record of how the efficiency, power and lifespan of equipment can be improved.

Forward-thinking companies can employ reverse engineering to create spares of business-critical components before they actually fail. This enables them to limit the effect a breakdown can have. To make things even more efficient, a firm can use any planned downtime to obtain the spare parts using reverse engineering and then use another period of planned downtime to conduct any repairs.

A final advantage of using reverse engineering services is that they can greatly reduce the lead time and cost of obtaining OEM parts.

Recieve a Custom Quote

Need a precision engineered component? Click below to receive a rapid quote from our team.

Or Call: 01457 866 614