Outsourcing and subcontracting are extremely common concepts in the IT and payroll industries for many years, however they only really became an option for the manufacturing sector following the 2008/2009 recession. This trend has continued ever since, with many companies recognising the benefits on offer.

Subcontracting is defined as the contractual process where a primary contractor delegates all or part of a job to a third party. While the third party will carry out the work under specific conditions, responsibility for the finished product remains with the primary contractor.

Taking the decision to subcontract precision engineering projects can provide your company with a number of different benefits and give you additional support when you need it most. We’ll outline just a few.

Sharing Expertise

There are a large number of specialities that come under the umbrella of engineering. To give themselves a chance of success, many companies will choose to base their operations around a select few and focus on becoming as proficient as possible in these areas. This approach enables manufacturers to build the ideal team to help them reach this goal.

Occasionally, a project may come through that requires expertise in another area of manufacturing that you may not be too familiar with. If you subcontract precision engineering to another firm that specialises in this particular area, you can benefit from their expertise and ensure that the project as a whole will be of the highest possible quality.

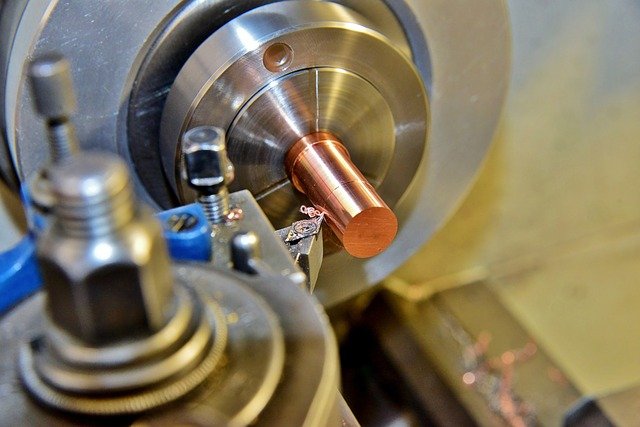

You could also come across a task that requires a specific type of machinery that you don’t have access to. By outsourcing some or all of the project to a third party who has access to this equipment will save you from having to purchase or hire it yourself – making it extremely cost-effective.

Drawing on the experience of other companies will also remove the need for potentially expensive training programmes that would be needed to plug in the knowledge gap.

Increased Productivity

Engineering projects will very often have a tight turnaround time. As a result, it is essential that your company has a smooth and free-flowing production line if it’s to keep up the pace.

A firm’s workflow process is usually much more efficient when workers are designated set tasks, rather than being expected to take on multiple different things at once. This enables staff members to be a lot more focused on what they’re doing and maintain productivity.

If you subcontract precision engineering tasks to third parties, you can effectively streamline your processes and reduce the need for staff members to multitask. This means your business will be much more likely to meet even the tightest of deadlines.

Keep Control of Costs

Large projects are quite notorious for having costs that spiral out of control. Choosing to subcontract precision engineering tasks or projects enables you to avoid the potential pitfalls associated with overrunning on time. This is due to the fact that you will pay the third party per task, rather than per hour.

Several industries suffer from a condition known as “optimism bias”, which is where companies typically underestimate the length of time projects will take. If you pay employees by the hour, this could be extremely expensive if the work goes on for longer than you expected.

By subcontracting precision engineering tasks to a third party and paying them on a per-project basis, the burden of cost and estimating how long the work will take falls upon them and not you.

Help with Larger Projects

There will come a point in time where your business must take on bigger projects if it wants to grow. This may mean having to take on tasks that are currently out of your capabilities – at least until you invest in growing your operations.

If you subcontract precision engineering tasks, you can gain a valuable resource that enables you to take on new and larger clientele. By sharing the load, you will no longer be restricted on the type or volume of work you can take on. This enables you to build a strong reputation and will assist in your efforts to grow your company.

Exciting Technologies

As we touched upon earlier, deciding to subcontract precision engineering gives you access to state-of-the-art machinery and specialist equipment that would be extremely expensive to purchase yourself – especially if it won’t be used very much. If you purchase the machinery yourself, you would also need to train up your workforce in using these machines, unnecessarily wasting time and money.

Outsourcing the work to a specialist will be a much more affordable option and also provides you with peace of mind, knowing that the work is being carried out by an expert who will always ensure that everything is completed to the highest standards.

Adapt to Economic Cycles

Every industry will experience periods of growth of contraction, and engineering is no exception. If you subcontract precision engineering, you can enable your company to adapt to these varying levels of demand. As a result, you can maintain a lot more flexibility by ramping up your capabilities as and when necessary.

An example of this can be found in the construction sector, which saw companies rely more on contractors following the 2018 economic crisis. This enabled the firms to utilise people who were ready and waiting to work straight away, rather than having to go through the laborious hiring process.

Why Subcontract Precision Engineering to EGL Vaughan

If you are looking to subcontract precision engineering tasks, look no further than EGL Vaughan. We are experts in all forms of manufacturing, from CNC milling and CNC turning to reverse engineering.

For over 40 years, we have cultivated a reputation for providing the highest quality precision engineering services to a wide range of industries, such as power generation and electricity. Our commitment to quality has even seen us accredited by some of the most prestigious bodies in the industry, something that we are incredibly proud of.

In addition, we are dedicated to offering our clients a five-star service. We will provide expert advice and support throughout the manufacturing process, from the initial quote to the final delivery of your project. It is for this reason that many of our clients choose to return to us time and time again.

For more information about how EGL Vaughan can help you, contact our team today or request a rapid quote.