Around half a century ago, the responsibility for crafting high-quality and precision-made items fell to human engineers. While this level of skill and expertise is still required in modern-day manufacturing, the high number of advantages of CNC milling when compared to more traditional techniques has made computerised manufacturing much more commonplace.

CNC machining as a whole is especially important in industries such as aerospace, marine automotive and medical and can be used to perform a wide range of complex processes routing, grinding, lathing and punching. The technology has completely revolutionised the industry and has played a large part in the resurgence of the UK manufacturing industry in the last couple of years.

In order to get a better understanding of why CNC machining has become so dominant, we’re going to take a look at the various advantages of CNC milling when compared to more traditional methods.

What is CNC Milling?

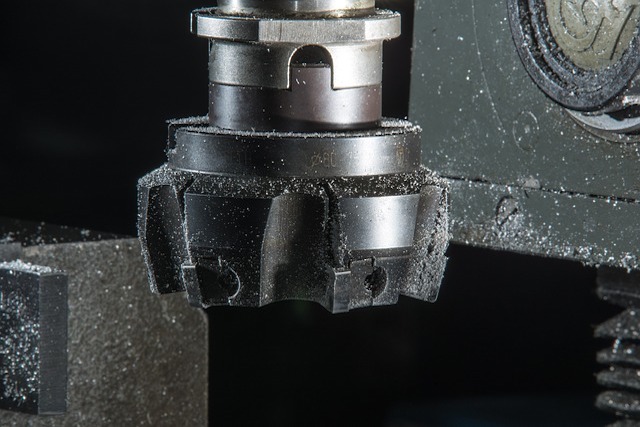

CNC Milling (also known as computer numerical control milling) is a method of manufacturing that utilises pre-programmed software to control machining tools. Digital instructions are first of all fed into the computer, which then automatically operates the machine to create precision-made components that match the specifications to the letter.

This method of manufacturing differs slightly from CNC turning, which involves the raw material being rotated at speed around a static cutting tool to craft materials to the right shape. CNC milling, on the other hand, keeps the material static and rotates the tool instead.

Advantages of CNC Milling

Now we’ve covered the basics of CNC milling, it’s time to explore the advantages of this manufacturing method over its more traditional counterparts.

Continuous Usage

Unlike human workers, CNC milling machines do not not need to take breaks, holidays or get sick. Once the instructions have been inputted into the computer and the machining begins, the manufacturing can take place throughout the day and night – only stopping once the task is completed or the machinery needs to be repaired.

This constant usage has completely transformed the industry and provided manufacturers with a way to drastically reduce their costs and improve productivity – something we’ve discussed in more detail in a previous blog post. Large projects that once might have taken weeks or even months to complete, can now be completed in a matter of days.

As a result, manufacturers are now able to take on a lot more projects than they could previously. This means they are able to make quite a bit more money in a shorter space of time – without drastically increasing their costs.

Consistency

One of the greatest advantages of CNC milling is that they can produce the same components over and over again in huge volumes. These manufactured parts will be exactly the same size, shape and dimensions – meaning everything will be created to match the right specifications every single time.

Even the most skilled of engineers will simply not be able to create the exact same component time and again. Instead, there will likely be tiny differentiations with each part.

Reduced Test Runs

Traditional machining methods require a lot of test runs to ensure that the components produced will match the specifications to the letter. This is because the operator will need to familiarise themselves with the process needed to manufacture the component and may make several mistakes in their first few attempts.

CNC milling machines have ways of avoiding these numerous test runs. They can use visualisation systems that enable the operator to see what will happen after the tool passes will finish, meaning the engineer will get a good idea of whether the component is going to match the specifications beforehand.

Design Retention

Once a design has been successfully loaded into the computer system and a perfect prototype created to ensure that everything is exactly as it should be, the software can easily retrieve the instructions whenever they are needed again. No matter if it is weeks, months or even years after the initial project was completed, having these instructions ready on file means there is no need to start from scratch when the components need manufacturing again.

This master file also ensures that regardless of outside circumstances, such as a change of machine operator, the CNC milling process can continue uninterrupted. Additionally, there is no need to keep up with versions of the design that might exist on paper, a disc, flash drive, another computer or anywhere else.

Capability

When used in conjunction with advanced computerised design software, CNC milling can create outputs that simply cannot be replicated by manually-operated machines – no matter the skill level of the engineers. This is because the CNC machines can produce components of any size, shape, texture or quantity that is needed, without any hassle or stress.

Get Expert Guidance with EGL Vaughan

If you are looking for help or guidance with CNC milling or CNC turning, you can rely on EGL Vaughan. We’ve amassed over 40 years of experience in providing expert precision engineering services to clients from all areas of industry – and are perfectly placed to assist you too.

We understand that no two precision engineering projects are the same. This is why we’ll take the time to gain a thorough understanding of your requirements so we can recommend what we believe is the best course of action for you.

One thing EGL Vaughan will never compromise on is quality. We have put together a robust quality control procedure that is regularly updated and ensures everything we produce conforms to even the strictest of specifications – first time, every time. It is this commitment that has seen us achieve several accreditations from respected industry bodies.

Another of our unique selling points is our ability to cultivate lasting working relationships. We understand that if you are looking for precision engineering services, you need to be working with a supplier you can trust. This is why we make ourselves available at every point during the manufacturing process, giving you the peace of mind you need that everything is being taken care of.

For more information about how EGL Vaughan can help you with your precision engineering projects, contact a member of our team today or request a quote if you already have a good idea of your requirements.