Reverse engineering is the process of thoroughly analysing how a part or component is constructed. Once this has been carried out, the manufacturer will be able to create an exact replica of the item, which can then be mass produced at a later date.

While this at first may come across as something highly illegal (and in some instances it is), the process of reverse engineering is actually a legally sanctioned method of copying a technology. This is because it has a whole host of important benefits for businesses in all areas of industry.

How does Reverse Engineering Work?

As the name suggests, a reverse engineering project involves working backwards from the finished product to understand the design and technology that was used in the item’s development. The process usually begins by taking apart the original component and then analysing, measuring and documenting the parts.

Once all this information has been collected, the manufacturer will then be able to determine how the part was originally constructed and should have everything they need to construct the product themselves. They will also be able to suggest improvements to the item to make it a better version of what it was before.

Although we will just be concentrating on its uses in manufacturing, reverse engineering is not just limited to mechanical components or assemblies. Products and systems such as computer software, chemical formulas and biological, chemical and organic matter can be reverse engineered as well.

What is Reverse Engineering Used For?

The process of reverse engineering has a multitude of uses in modern-day manufacturing. These include:

Product Development

The improvement of products is actually a key driver of reverse engineering projects. In today’s fast-paced and competitive business environment, it is essential for companies to do everything they can to stay ahead of the curve.

This is why engineers continuously need to find new ways to innovate and improve new ideas and existing products throughout the lifecycle of a product. For them to be able to do this, they need to have as much data as possible to help them refine and improve a product’s working capabilities and assembly process.

When it comes to product improvement, the main goals of reverse engineering are:

- Refining features (eg usability)

- Improving product performance

- Reducing manufacturing costs

- Replacing an existing product with an updated version

By conducting a thorough review of a product’s development process, reverse engineering allows manufacturers to make important changes that ensures the item can remain competitive and relevant as time progresses.

Obsolescence Issues

Reverse engineering is extremely useful when parts are no longer manufactured but are still used in existing technology and machinery. When a company suffers a breakdown or malfunction, reverse engineering will typically be the only way to fix the problem without having to completely replace the entire machine.

Manufacturers can also rely on reverse engineering when they are working with machinery that is on the verge of obsolescence themselves. By working out how the machine was constructed in the first place, it is possible to find potential improvements to extend its lifespan even further.

Missing Design Documents

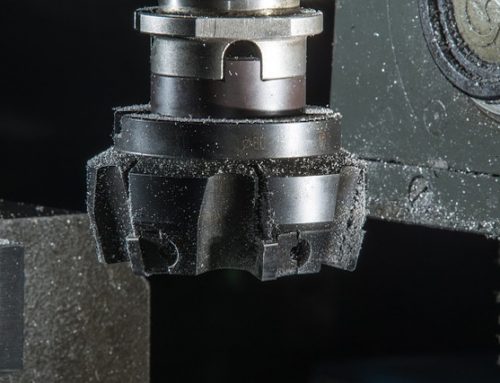

Creating precision engineered products using conventional methods relies on the use of detailed digital instructions that can be fed into the CNC milling and CNC turning machines. But what happens if these documents don’t exist or have been mislaid?

This is where reverse engineering can help. By deconstructing a component to find out how it was created, manufacturers are able to not only recreate the part from scratch – but also develop proper digital instructions that can be used to produce the component whenever it is needed.

On top of this, reverse engineering can also help manufacturers suggest improvements to how the component was created and enhancements to the production process to make everything as cost-effective as possible.

Product Failures

Product failures can be a huge headache for companies, so when something does go wrong it is essential to find out what happened as soon as possible – then prevent it from ever happening again. Reverse engineering can help manufacturers understand the reasons for the failures and, after extensive investigations and improvements, extend the product’s functional lifecycle period.

Company Takeovers

When one company buys out another, the purchasing party may find themselves owning products for which it doesn’t have the full manufacturing knowledge for. Much like in situations where complete digital instructions are missing, reverse engineering can be used to fill in the gaps and ensure the products can continue to be created without a hitch.

Is Reverse Engineering Right for You?

No two manufacturing processes are ever the same. This means that there is no one-size-fits-all solution to every problem. To combat this, the team at EGL Vaughan will work with you to fully understand your needs and recommend what we believe is the right course of action.

Even if you are not quite sure about the intricacies of your project, our team will sit with you and work out a plan to achieve your goals. Whatever you require, EGL Vaughan can assist.

Why Work with EGL Vaughan

If you are looking for reverse engineering services, EGL Vaughan is here to help. We’ve amassed over 40 years of experience in providing the highest quality precision engineering to companies in the power and energy industries.

No matter what your project entails, you can rely on EGL Vaughan to deliver the finished products on time and on budget. We’ll also provide expert and essential support throughout the entire process – so you can rest assured that everything is being taken care of.

We will never compromise on quality and have put together a robust procedure that ensures everything is produced to satisfy even the most demanding of requirements. This is especially important for components that will be subjected to harsh environments and conditions. We’ll also provide you with a rapid quote, so you can rely on us when time is of the essence.

To find out more about how EGL Vaughan can help you, request a quote or contact our team today.