Precision engineering has long been at the forefront of one industrial revolution after another. From the very first industrial mills, right the way through to modern-day CNC Milling and CNC Turning services, manufacturers have consistently been the backbone of a wide range of industries – and the green and renewable energy sector is no different.

Dubbed by some as the Sustainable Revolution, there has in recent years been a seismic shift away from the reliance on traditional fossil fuels and instead gravitating towards cleaner and renewable forms of energy. These include wind, solar, geothermal and hydroelectric power.

Just like generating energy through the use of fossil fuels, precision engineering plays a huge and important role in the production of green and renewable energy. But how do the benefits of precision contribute to the ever-growing green energy sector?

Why Focus on Green and Renewable Energy?

Global warming and climate change have had a significant impact on the world’s weather and been the catalyst for several environmental disasters. It has long-since been understood that our overreliance on fossil fuels has contributed to this problem, which is why countries across the globe have committed to looking for cleaner and less-damaging alternatives.

In addition to this, we are also depleting our reserves of fossil fuels, which still contributes to a large proportion of energy production. Because of this, it is essential that we move closer towards the decarbonisation of the energy sector.

Now that we’ve discussed why helping the pursuit of green and renewable energy sources is so important, we’ll move onto outlining several benefits of precision engineering that contribute to this essential industry.

Innovation

The green and renewable energy sector is constantly evolving. Each new development brings different challenges and requires new ways of thinking. Since sustainability and efficiency are important, it is essential that every piece of equipment and machinery, no matter how small, performs at its absolute best.

Precision engineering enables manufacturers to constantly find ways to improve on existing ideas and come up with exciting new products. Using the process of reverse engineering, it’s possible to conduct a thorough review of a product’s development process to highlight areas that can be changed to ensure everything is as efficient as possible.

By using precision engineering techniques, it’s also possible to test out design ideas to ensure that new products are viable and will work exactly as intended, before they are released onto the wider market. Identifying and fixing potential pitfalls at this early stage guarantees there are no nasty surprises further down the line – potentially saving a lot of time and money.

Reliability

As a society, we are becoming more and more reliant on power and especially on electricity. This makes it essential that there are absolutely no interruptions in supply. The sudden loss of electricity can have wide-ranging effects, from the shutdown of transport networks to major disruption in people’s everyday lives.

Every single component needed for the green and renewable energy industry must therefore be built to last. This is something that precision engineering guarantees. By using robust quality control procedures before new components are released, manufacturers can ensure that every single item can conform to even the most stringent requirements and can be relied upon to perform for many years to come.

Given that the production of many forms of green and renewable energy involves mechanisms being subjected to harsh conditions, every single part and component has to be robust. Turbines used in the offshore wind industry, for example, are routinely battling against the elements – making it crucial all of the parts involved are extremely durable. This is something that precision engineering excels at.

Accuracy

Mechanisms involved in the production of green and renewable energy are incredibly complicated and are each made up of extremely intricate parts. To ensure that everything works as it should, each component must conform to exact specifications and be accurate to minute tolerations.

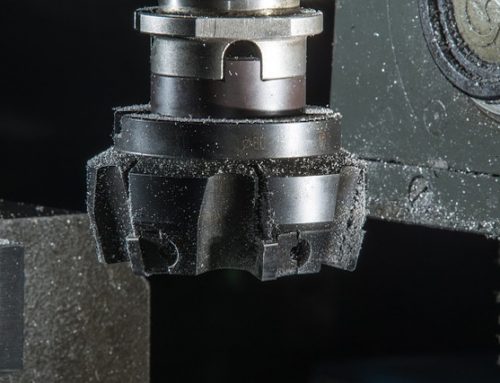

The use of precision engineering techniques, especially CNC machining, makes all of this entirely possible. By completely taking away the possibility of human error, manufacturers can ensure that absolutely everything they produce conforms to the exact specifications, no matter how strict.

Mass Production

The green and renewable energy industry is vast. Because of this, parts and components need to be produced on an extremely large scale, with each one being exactly the same as the last. This level of production must also take place within very tight timeframes, meaning manufacturers have to work fast to ensure there is no delay.

All of this is entirely possible using precision engineering. By adopting CNC machining techniques, components can be produced on a large scale, with each one being the exact same dimension and conforming to even the most demanding specifications. The use of computerised machinery also means that products can be manufactured late into the night and on weekends, so that even the tightest of deadlines can be met.

Specialism

A high-quality precision engineering company will be experts in their field. Having this in-depth knowledge of what the green and renewable energy industry requires means clients can be sure that absolutely everything produced by their supplier is fit for purpose. This gives the client complete peace of mind that everything will be taken care of and their needs will be met first time, every time.

Why Work with EGL Vaughan

EGL Vaughan has lived and breathed the green and renewable energy industry for over 40 years. During this time, we have amassed a wealth of experience and knowledge, making us a trusted supplier for organisations large and small. This means you can be totally confident that everything we produce is not only of the highest quality, but also can be trusted to stand the test of time.

We were founded on the motto “if you need it, we can build it”, meaning we are able to deal with projects of all shapes and sizes. We are also able to effortlessly modify our processes to ensure that we can meet all of your individual requirements.

Our robust quality control procedures ensure that everything we produce conforms to even the most strict specifications, while we also offer expert advice and support throughout the entire manufacturing process – so you can rest assured that everything is being taken care of. It is for this reason that many clients return to us time and again, whenever they need precision engineering services.