If you’re not familiar with the process, CNC turning and milling may seem exactly the same. After all, they appear to be very similar processes and achieve similar results.

Understanding the difference between CNC turning and milling, however, will enable you to decide which method best fits the requirements of your project – potentially saving you a lot of time and money.

CNC Machining

Before we explain the difference between CNC turning and milling, we’ll first of all explore the overarching term that is used to describe both processes. Indeed, some customers may ask for CNC machining services, meaning it is up to the manufacturer to decide which method will best suit their requirements.

The CNC in CNC machining stands for Computer Numerical Control and involves feeding instructions into a machine which then controls the lathes, mills, routers and grinders. Excess material is then removed from the raw material to create the desired part to exact specifications.

The Difference Between CNC Turning and Milling

Put simply, the difference between CNC turning and milling is which part actually moves – the machine itself or the raw material. CNC milling processes involve the material being held in place while the cutting tools rotate around it. CNC turning, on the other hand, requires the tools to maintain in the same place while the material is rotated at speed to create the exact shape.

Although this is quite simplistic, there is much more to the processes than meets the eye. Here are a few more ways in which there is a difference between CNC turning and milling:

- Tool Features: The cutting tool is single point for CNC turning and multi-point in milling

- Uses: CNC milling is better suited for machining flat and irregular surfaces, while CNC turning is mainly used for working on cylindrical or conical surfaces

- Cutting: CNC turning involves continuous cutting, with the tool maintaining constant contact with the workpiece. CNC milling uses intermittent cutting, where the cutting teeth continuously engage and disengage from the raw material

- Chips: CNC milling always produces discontinuous chips, while CNC turning can produce discontinuous, continuous and fragmented chips

Now that we’ve explained the difference between CNC turning and milling, we’ll now go into a bit more detail about each process.

What is CNC Turning?

While you may think that CNC turning is a relatively new invention, it is actually derived from one of the oldest and simplest forms of creating parts – the use of the lathe. The machines are either horizontal or vertical depending on the weight and tolerance of the workpiece and the raw materials used are usually round in shape, but can also be square or hexagonal.

The main function of a CNC turning centre is to rotate (‘turn’) the workpiece, while the machine’s tools move in to shave away excess material to create the desired shape. To begin with, the material is held in place by an instrument known as the “chuck”, which then spins at different speeds according to the specifications of the machine.

The very first lathes used to be operated manually by using a series of turn wheels. These wheels would then move the chuck while holding the workpiece in order to create the back and forth motion required for cutting. Fast forward to today and modern CNC turning machines are controlled numerically and without the need for constant manual supervision.

CNC turning is more commonly used to create cylindrical parts, such as custom hollow tubing and shafts. Although it is possible to manufacture these components using 5-axis machining, it is much more cost-effective and efficient to use the turning method.

If you’d like more details about CNC turning and the type of parts it can make, our blog can help.

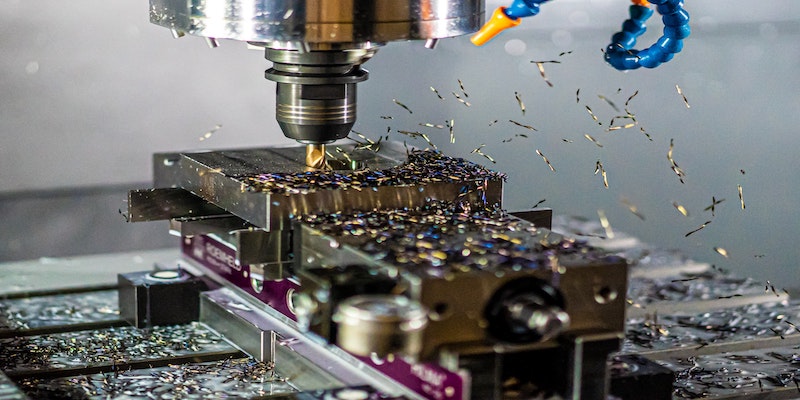

What is CNC Milling?

Unlike CNC turning, which usually only uses a single point cutting tool, CNC milling is performed using various axes. The more traditional of these is the 3-axis, which enables the cutting tool to move in three directions – known as X, Y and Z.

Restricting the process to only three directions can set a few limits to the geometry of the part that can be created, it is enough to complete the vast majority of the processes that require milling services. There are also a wide range of different milling tools that provide different cutting methods such as end milling, hollow milling and face milling.

CNC milling also offers machining on four or more axes, which include the rotation of the tool and worktable. These provide an extra dimension of flexibility. The most common of these machines run on fives axes, which are able to create pretty much anything that can be manufactured by CNC machining.

It is worth bearing in mind, however, that using a five axis machine is more expensive than its three axis counterpart. Your precision engineering supplier will be able to talk through your requirements to decide which machine is best suited for your project so that you are not spending money unnecessarily.

This high level of capability makes CNC milling suitable for more complex components, such as custom tooling, intricate mechanisms, enclosures and engine parts.

For more information about the CNC milling process, check out our blog on the subject.

Why Work With EGL Vaughan

Whether you’re looking for CNC turning, milling, or any other precision engineering service, you need a supplier you can rely upon. The components you need must be of the highest quality and built to stand the test of time.

This is where EGL Vaughan can help. We’ve amassed over 40 years of experience in producing industry-leading precision engineered components and are experts in forming lasting relationships with our clients that have seen them return to us time and again.

We will never compromise on quality and have stringent control practices in place to ensure that everything we produce can meet even the most demanding of standards and specifications. It is this constant pursuit of quality that has seen us receive a multitude of accreditations in recognition of our efforts.

We also guarantee to provide you with a rapid quote and are able to deal with orders of all shapes and sizes – whatever you need, we can make it. To find out how EGL Vaughan can help you with your precision engineering needs, request a quote today or contact a member of our team.