Precision Engineering

If you’re looking for high-quality precision engineering services, you can rely on EGL Vaughan to help.

| Fast turnaround | UK Manufactured |

|---|

| High Quality | Cost-Effective |

A Trusted Precision Engineering Supplier to Some of the UK’s Leading Companies

Precision Engineering Services Built Around You

EGL Vaughan understands that no two precision engineering projects are alike and there are no one-size-fits-all solutions that can help. Each set of circumstances is completely unique and personal to every client, so it is essential that a manufacturer gains a thorough understanding of the situation before they even think about starting work.

This is exactly the approach that EGL Vaughan takes with each and every one of our clients. We will work with you to get in-depth knowledge of your circumstances and requirements, before using our decades of experience to recommend the best solution for you. We will then manufacture your components according to your exact specifications.

We believe in providing our clients with an all-encompassing and holistic service that begins as soon as you make your first enquiry. We guarantee that you’ll receive a quote in just 24 hours, and your completed order as soon as possible – often in a few weeks if not days and with absolutely no compromise on quality whatsoever.

EGL Vaughan believes in creating lasting relationships with our clients. This is why we provide expert advice and support throughout the entire precision engineering process, from initial enquiry all the way to delivery. By doing this, we give our clients the peace of mind they need that they are dealing with a company they can rely upon. It is for this reason that our clients come back to us time and again.

Common Uses

- Electrical

- Transmissions

- Marine

- Energy

- Engineering Support

- Security

- Rail

Recieve a Custom Quote

Need a precision engineered component? Click below to receive a rapid quote from our team.

Or Call: 0161 511 5311

What is Precision Engineering?

Precision engineering is classed as a subdivision of manufacturing and gets its name from the extremely high level of accuracy that is needed to carry out the service. The concept has been around for hundreds of years in some format or another, only changing with the invention of new technologies and ways of working.

Nowadays, precision engineering services are most commonly used to mass-produce small parts and components, eliminate the risk of human error, increase business efficiencies and create new and unique precision parts.

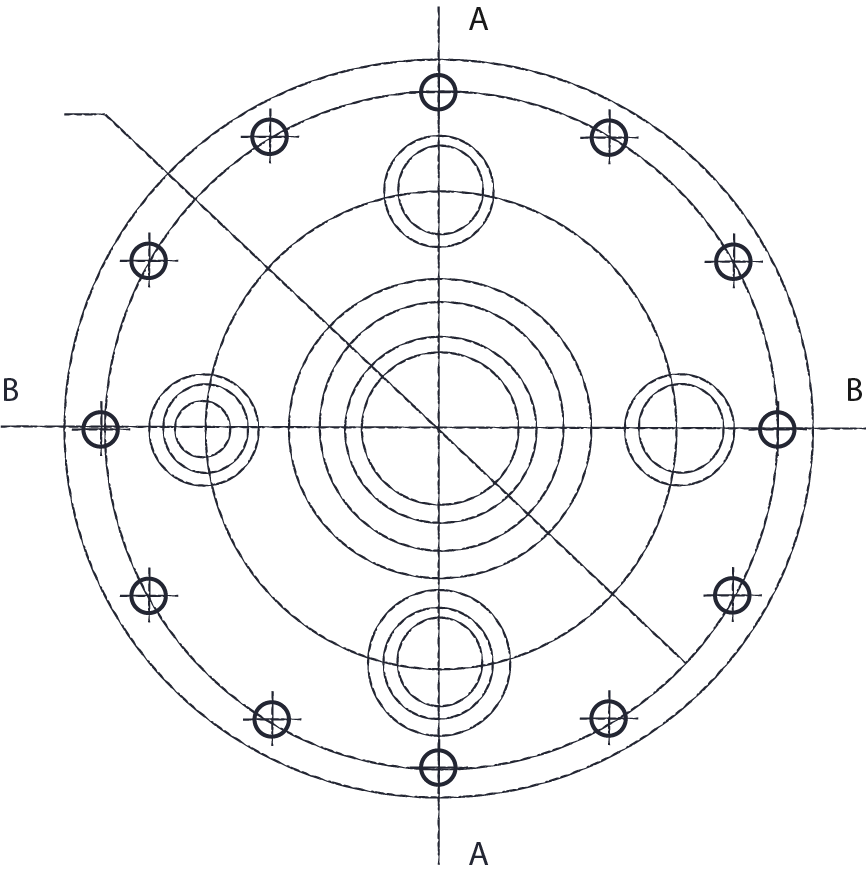

The two main types of precision engineering services are CNC Milling and CNC Turning. These disciplines use computer aided design (CAD) software to read digital instructions and design specifications, before feeding this information to the computer. The computer will then control the machining tools to shape the raw material to match the specifications given.

How Important is Precision Engineering?

With each advancement in technology, machines become ever more complicated and the parts used to build them become increasingly intricate. This is where precision engineering excels. Using this discipline, manufacturers are able to mass-produce even the most complex components with ease – saving a great deal of time and money, while also reducing the amount of waste.

The components that are manufactured using precision engineering services are often subjected to extreme conditions and pressures. If even the smallest of parts fails, it could have disastrous consequences. Using precision engineering techniques allows manufacturers to produce components that can withstand the test of time and deal with all manners of situations.

Put simply, modern-day manufacturing would certainly not be where it is without the rise of precision engineering services. Manual production is not capable of coping with deviations in measurements and the demand to create the exact same component over and over again. Only precision engineering can deal with the need for finer and finer detail and an increase in mass production. The UK manufacturing sector has really experienced a boom in recent years, and precision engineering has been the driving force.

What Materials are Used in Precision Engineering?

One of the many advantages of precision engineering services is the versatility that they offer. The most common material used by manufacturers in this field is metal, which can be turned into a huge variety of components. For example, aluminium (the most popular metal used in precision engineering) can be used to create parts such as electronic housings, shafts, gears and aircraft fittings.

Plastics are also commonly used in precision engineering. Nylon, which is extremely simple to machine, can be manufactured into insulators, bearings and products used in injection moulding. PVC, meanwhile, is popular due to its cost-effectiveness and can be found in items ranging from toys to water and gas pipes. Finally, ceramic PEEK is ideal for creating connectors, switches and test sockets.

While metals and plastics are the most commonly-used materials in precision engineering, wood can also be used. This extremely sturdy material is ideal to handle wear and tear, but can be quite expensive and usually requires specialist cutting equipment. Meanwhile, foam based materials are a fantastic choice for carrying out test runs on a project – before moving onto a more expensive material.

Recieve a Custom Quote

Need a precision engineered component? Click below to receive a rapid quote from our team.

Or Call: 01457 866 614